Tel: +86-13587713206 / +86-577-61389776丨E-mail: nancy4046@hotmail.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-06 Origin: Site

Selecting the right cable accessories is essential for high-voltage projects. Heat Shrink and Cold Shrink technologies are commonly used for cable terminations, but which one is best for your project?

In this article, we will explore the advantages and differences between Heat Shrink for High Voltage and Cold Shrink for High Voltage, particularly focusing on 24KV Heat Shrink Cable Terminations and Joints and 35KV Cold Shrink Cable Terminations and Joints. You’ll learn which technology is the most suitable for your specific needs.

Heat Shrink technology uses thermoplastic materials that shrink when exposed to heat, creating a tight seal around cable connections. This method involves sliding a heat shrinkable tube over the cable, then applying heat using a heat gun or flame. The heat causes the tube to contract tightly around the cable, providing insulation and protection from moisture, contaminants, and mechanical stress.

Key Features and Benefits:

● High Insulation Resistance: Heat Shrink offers superior insulation properties, protecting against electrical leakage and enhancing the durability of the cable terminations.

● Chemical Resistance: Heat Shrink materials can be engineered to resist harsh chemicals, making them ideal for use in industrial and outdoor environments.

● Cost-Effective: Heat Shrink accessories are typically less expensive compared to Cold Shrink alternatives, making them suitable for a wide range of applications, especially in budget-conscious projects.

● Versatility: Heat Shrink is available in various sizes, making it adaptable for different cable sizes and voltage ratings, such as 24KV Heat Shrink Cable Terminations and Joints.

Cold Shrink technology uses pre-stretched elastomeric materials, typically made from silicone or rubber, that contract once the support core is removed. These materials shrink to form a tight, secure seal around the cable, providing insulation and environmental protection. Unlike Heat Shrink, Cold Shrink does not require external heat sources, making it safer and easier to install in certain environments.

Key Features and Benefits:

● Tool-Free Installation: Cold Shrink installations require no heat, flame, or specialized tools, simplifying the process and reducing installation time, especially in confined or hazardous spaces.

● Environmental Resistance: Cold Shrink is highly resistant to moisture, UV rays, and chemicals, making it an ideal solution for outdoor and industrial installations.

● Long-Term Reliability: Cold Shrink offers excellent long-term performance, as its materials maintain their sealing properties over time, even under extreme environmental conditions.

● Safety: The lack of heat during installation reduces the risk of fire and damage to the cables, which is particularly beneficial in sensitive locations like oil refineries or chemical plants.

● Use Cases: Cold Shrink is particularly effective for 35KV Cold Shrink Cable Terminations and Joints, as it ensures reliable and long-lasting cable protection.

Heat Shrink Installation Process:

The installation of Heat Shrink terminations requires the use of a heat source, such as a gas torch or heat gun. The process involves placing the heat shrink sleeve over the cable connection and applying heat evenly across the surface. While effective, this process can be time-consuming and requires trained personnel to ensure proper application. Heat Shrink installations also require careful attention to prevent overheating or under-shrinking, which can lead to gaps or poor seals.

Cold Shrink Installation Process:

Cold Shrink offers a simpler and faster installation process. It comes pre-expanded on a support core, which is removed during installation. As the core is pulled out, the elastomeric material naturally contracts, forming a secure, tight seal around the cable. No external heat is needed, reducing installation time and complexity. This makes Cold Shrink ideal for projects where speed and safety are crucial.

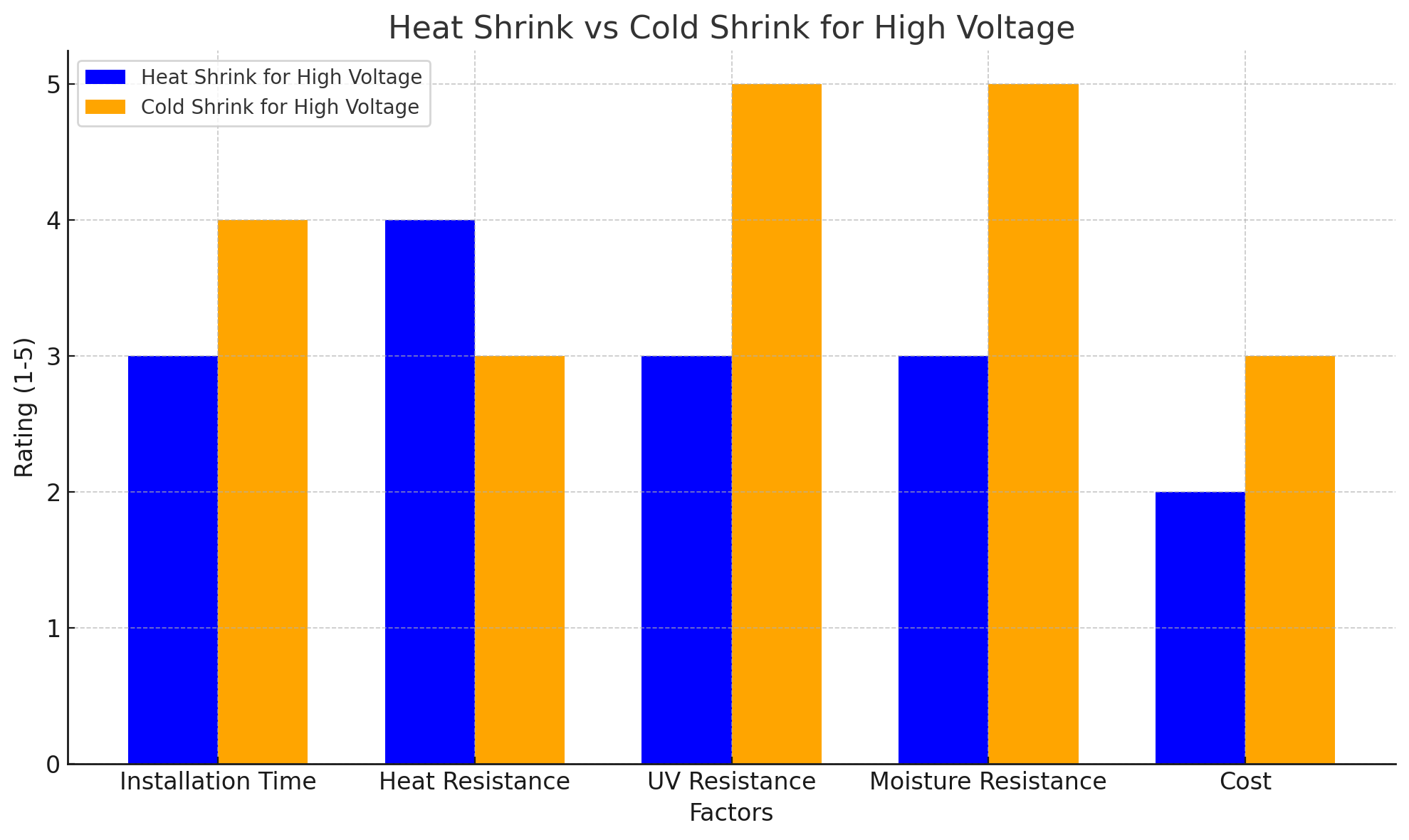

Comparison:

● Heat Shrink requires specialized tools and careful handling of heat sources, which can lead to slower installation times and increased safety risks.

● Cold Shrink, on the other hand, offers a tool-free installation process that can be completed in a fraction of the time without the need for additional heat sources.

Heat Shrink Performance:

Heat Shrink provides excellent insulation and sealing, ensuring that the cable connections are protected from external elements such as moisture, dust, and chemicals. It is highly effective in high-voltage applications, offering long-lasting durability under various environmental conditions. However, Heat Shrink’s performance can be impacted if the installation process is not done correctly, leading to potential issues such as moisture ingress or poor sealing.

Cold Shrink Performance:

Cold Shrink provides an equally reliable seal, with the added advantage of being able to perform well in extreme temperature ranges. It is highly resistant to moisture and environmental pollutants, ensuring that the cable terminations remain intact even in challenging conditions. Cold Shrink’s materials are less prone to degradation over time compared to Heat Shrink, making them a more reliable option for applications exposed to harsh environmental factors.

Comparison:

● Heat Shrink excels in applications requiring strong chemical and mechanical resistance, but its performance depends heavily on proper installation.

● Cold Shrink offers a more consistent and durable seal over time, especially in environments with high moisture levels or extreme temperatures.

Feature | Heat Shrink for High Voltage | Cold Shrink for High Voltage |

Installation Method | Requires heat source | No heat required, pre-stretched material |

Time to Install | Longer, requires equipment | Faster, tool-free installation |

Performance in Extreme Weather | Strong resistance to UV and chemicals | Superior moisture and UV resistance |

Cost | Generally lower upfront cost | Higher initial material cost, but less labor-intensive |

Ideal Voltage Range | Up to 35KV | Up to 35KV |

Applications | Outdoor, underground systems | Confined spaces, hazardous environments |

Best Use Cases for Heat Shrink:

● Outdoor Installations: Heat Shrink’s ability to form tight seals makes it ideal for outdoor installations, especially in areas that are exposed to weather and UV rays.

● Underground Systems: Heat Shrink is commonly used in underground cable systems due to its reliable sealing properties, protecting cables from moisture and dirt.

● Industrial Applications: For environments where high mechanical strength and chemical resistance are crucial, Heat Shrink provides the necessary protection.

Recommended Voltage Levels:

● Heat Shrink is suitable for high-voltage applications, especially for systems rated up to 35KV. It is ideal for installations in power transmission networks, industrial plants, and utility sectors.

Best Use Cases for Cold Shrink:

● Confined Spaces: Cold Shrink is particularly useful for installations in tight or hard-to-reach spaces where using a heat source is not feasible.

● Hazardous Environments: In environments where safety is a priority, such as oil and gas facilities, Cold Shrink offers a tool-free, heat-free solution.

● Outdoor and Wet Locations: Cold Shrink’s superior moisture resistance makes it an excellent choice for outdoor applications, including renewable energy projects like wind farms.

Recommended Voltage Levels:

● Cold Shrink is ideal for 35KV Cold Shrink Cable Terminations and Joints, providing reliable protection against environmental stressors in high-voltage applications.

Application Type | Recommended Product | Voltage Range |

Outdoor Systems | Heat Shrink for High Voltage | Up to 35KV |

Industrial Systems | Heat Shrink for High Voltage | Up to 35KV |

Confined Spaces | Cold Shrink for High Voltage | Up to 35KV |

Hazardous Environments | Cold Shrink for High Voltage | Up to 35KV |

Moisture-prone Areas | Cold Shrink for High Voltage | Up to 35KV |

Cost of Heat Shrink:

Heat Shrink materials typically have a lower initial cost compared to Cold Shrink. However, the overall cost of installation may increase due to the need for specialized tools, heat sources, and additional labor.

Cost of Cold Shrink:

Cold Shrink products generally have a higher upfront cost for materials. However, the installation process is quicker and does not require additional tools or heat sources, resulting in potential savings in labor costs.

Maintenance Requirements for Heat Shrink:

Heat Shrink systems generally require minimal maintenance, but improper installation can lead to degradation over time, especially in extreme weather conditions. Regular inspections are necessary to ensure long-term performance.

Maintenance Requirements for Cold Shrink:

Cold Shrink systems are designed for longevity, with minimal maintenance needs. The lack of heat application during installation reduces the risk of failure, and the materials are more resistant to environmental factors, reducing the need for frequent repairs.

Performance in Heat, Cold, and UV Exposure:

Heat Shrink products are effective in environments with high UV exposure and fluctuating temperatures. However, the integrity of the seal may weaken if the product is exposed to extreme temperature shifts or prolonged UV radiation.

Moisture, Chemicals, and UV Resistance:

Cold Shrink excels in environments where moisture, chemicals, and UV exposure are prevalent. The silicone and rubber materials used in Cold Shrink products ensure a reliable seal that resists degradation over time.

Both Heat Shrink and Cold Shrink technologies offer effective solutions for high-voltage cable terminations. Heat Shrink excels in providing strong chemical and mechanical resistance, making it ideal for outdoor and industrial systems up to 35KV. In contrast, Cold Shrink provides faster installation, making it the preferred choice for confined spaces and hazardous environments.

For high-voltage systems requiring minimal downtime and exposure to extreme conditions, Cold Shrink offers reliable performance, especially in 35KV Cold Shrink Cable Terminations and Joints. Anlian Electric offers these high-quality solutions, ensuring long-term reliability in demanding projects.

A: Heat Shrink for High Voltage uses heat to create a tight seal, providing excellent insulation and durability. Cold Shrink for High Voltage uses pre-stretched elastomeric materials that contract without heat, offering quick installation and safety, especially in confined spaces.

A: 24KV Heat Shrink Cable Terminations and Joints are ideal for high-voltage systems requiring robust insulation and resistance to chemicals and mechanical stress, often used in outdoor and industrial applications.

A: 35KV Cold Shrink Cable Terminations and Joints offer faster installation, minimal downtime, and superior performance in harsh environments, making them perfect for areas exposed to extreme weather conditions.

A: Cold Shrink for High Voltage offers a tool-free, quick installation process, enhanced safety, and performance in challenging environments like offshore, underground, and hazardous locations.

A: Heat Shrink for High Voltage requires a heat source for installation, while Cold Shrink for High Voltage simply requires removing a supporting core, making it faster and easier to install.