Tel: +86-13587713206 / +86-577-61389776丨E-mail: nancy4046@hotmail.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-03 Origin: Site

Cold shrink cable terminations are revolutionizing offshore cable installations. But why are they becoming the go-to solution? In this article, we will explore how cold shrink technology outperforms traditional methods, particularly in harsh offshore environments.

You will discover the unique benefits of cold shrink cable terminations, including their ease of installation, safety advantages, and long-term performance. Learn how this technology enhances cable reliability and reduces operational costs in offshore projects.

The Technology Behind Cold Shrink

Cold shrink cable terminations are made from elastomeric materials such as silicone rubber, which are pre-expanded and wound onto a rigid plastic core. The core is removed during installation, allowing the material to contract around the cable, forming a tight, permanent seal. This mechanism, known as "elastic memory," provides reliable insulation and protection for cables.

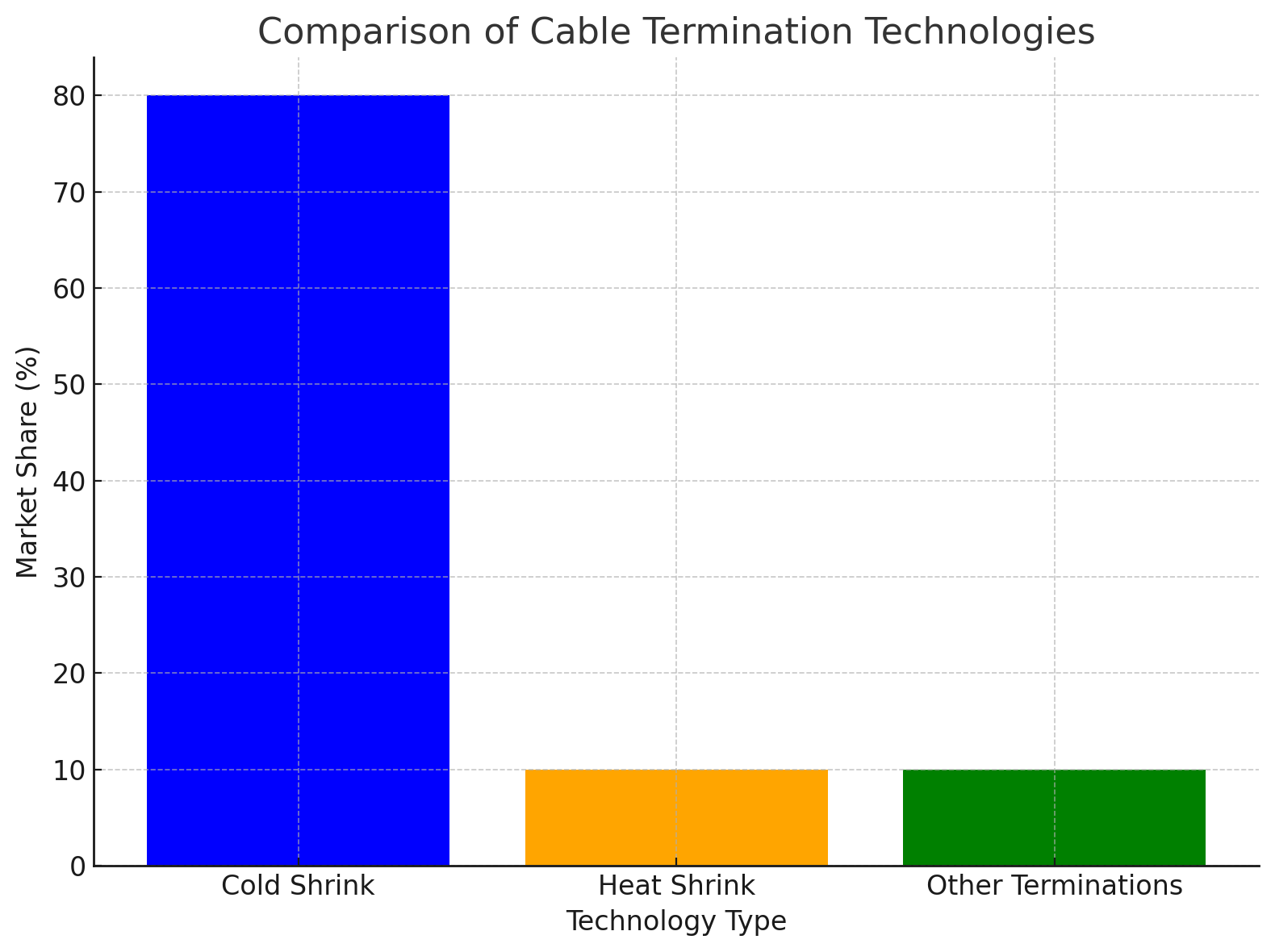

How Cold Shrink Compares to Other Termination Technologies

In contrast to heat shrink terminations, which require a heat source for installation, cold shrink terminations offer a simpler, tool-free installation process. Heat shrink requires careful application of heat, while cold shrink only requires pulling out the core, making it a safer and quicker option, especially in hazardous offshore environments.

Ease of Installation

Cold shrink cable terminations are remarkably easy to install. Unlike heat shrink terminations, which require the use of heat guns or torches, cold shrink installations require no special tools. The pre-stretched material contracts onto the cable as the core is removed, creating a tight seal with minimal effort. This is particularly valuable in offshore applications where space and time are limited.

Safety Benefits

The absence of heat in the installation process significantly enhances safety. Offshore installations often occur in confined or hazardous environments where the use of open flames or heat can be dangerous. Cold shrink terminations eliminate these risks, making them a safer alternative.

Durability and Resistance

Cold shrink terminations are highly durable, offering excellent resistance to UV radiation, moisture, and extreme temperature fluctuations. In offshore environments, where cables are exposed to harsh weather, saltwater, and UV rays, cold shrink technology provides a long-lasting solution that ensures continuous protection for the cables.

Advantage | Description |

Tool-Free Installation | No need for heat guns or other tools, reducing the risk of burns. |

Superior Environmental Resistance | Excellent UV, salt, moisture, and temperature resistance for offshore environments. |

Fast Installation | Reduces downtime in offshore projects by enabling quick and easy installation. |

Durability | Long-lasting with minimal maintenance, ensuring reliability in harsh conditions. |

Protection from Moisture and Contaminants

Cold shrink cable terminations provide superior protection against moisture and contaminants, which are major concerns in offshore applications. The tight seal created by cold shrink material prevents water ingress, salt exposure, and other environmental contaminants from entering the cable, ensuring that electrical systems remain reliable and safe.

Long-Term Performance

Cold shrink terminations are known for their long-term performance in harsh offshore environments. Due to their robust construction and elastic properties, they are less prone to wear and tear, ensuring consistent performance over time. Their low failure rates make them a preferred choice for offshore installations that require continuous, reliable operation.

Faster Installation

The quick and straightforward installation process of cold shrink terminations helps reduce offshore downtime. Unlike heat shrink, which can take longer to install and requires additional equipment, cold shrink terminations can be quickly installed by simply removing the core. This leads to reduced labor costs and faster project completion times.

Impact on Offshore Projects

Offshore projects often involve tight schedules and challenging environmental conditions. By using cold shrink cable terminations, project managers can reduce installation time, minimize safety risks, and improve the overall efficiency of their projects, which is crucial in offshore settings where downtime can be costly.

High UV Exposure

Cold shrink terminations are highly resistant to UV radiation, making them ideal for offshore applications where cables are exposed to constant sunlight. The UV-resistant materials ensure that the terminations do not degrade or weaken over time, providing long-term protection for the cables.

Temperature Extremes

Cold shrink technology performs well in extreme temperature conditions, ranging from extreme cold to high heat. Offshore environments can experience drastic temperature fluctuations, and cold shrink terminations maintain their performance regardless of these changes, ensuring that the cables remain protected and insulated.

Condition | Performance of Cold Shrink Cable Terminations |

UV Exposure | High resistance, preventing material degradation in constant sunlight. |

Temperature Extremes | Performs well in both extreme cold and high heat environments. |

Moisture and Salt Resistance | Protects against moisture ingress and salt fog, common in offshore environments. |

Corrosion Resistance | Helps prevent corrosion, a significant concern in offshore cable installations. |

Resistance to Harsh Weather

Cold shrink cable terminations are designed to withstand harsh weather conditions, including high winds, salt fog, and rain. These conditions are common in offshore environments, and the durability of cold shrink technology ensures that cables remain protected from moisture and corrosion.

Corrosion Prevention

The materials used in cold shrink terminations are highly resistant to corrosion, which is a major concern in offshore applications. Saltwater exposure can cause significant damage to cables over time, but the protective seal provided by cold shrink technology helps prevent corrosion, ensuring the longevity of the cables and reducing the risk of failure.

Step-by-Step Installation

Cold shrink cable terminations offer a straightforward installation process. The process involves cleaning the cable, positioning the pre-expanded tubing over the cable end, and pulling out the core to allow the material to contract. This simple method eliminates the need for heat or specialized tools, making it ideal for offshore applications where space and time are limited.

No Need for Heat or Special Tools

Since cold shrink technology does not require the application of heat or the use of specialized tools, it significantly simplifies the installation process. This makes cold shrink the preferred choice for offshore installations where safety, efficiency, and speed are crucial.

Low Maintenance Requirements

Cold shrink terminations are known for their minimal maintenance requirements. Once installed, they provide reliable and long-lasting protection for the cables, requiring little attention over their lifespan. This is particularly beneficial in offshore environments, where regular maintenance can be difficult and costly.

Long-Term Performance

Cold shrink cable terminations have a proven track record of performance in harsh offshore conditions. Their ability to maintain a tight seal, even in extreme weather and temperature conditions, ensures that the cables remain insulated and protected for many years, reducing the need for frequent repairs or replacements.

Key Differences

Cold shrink and heat shrink cable terminations serve the same purpose but differ in their installation methods and performance characteristics. Heat shrink requires a heat source, making it more time-consuming and riskier to install in certain environments. Cold shrink, on the other hand, can be installed quickly and safely without the need for heat, making it a better option for offshore applications.

Which Is Best for Offshore Environments?

In offshore environments, where safety and efficiency are paramount, cold shrink technology is the better choice. Its simplicity, speed, and ability to function in challenging conditions make it ideal for offshore cable terminations.

Feature | Cold Shrink Cable Terminations | Heat Shrink Cable Terminations |

Installation Method | Tool-free, no heat required | Requires heat and specialized tools |

Safety | No open flames, safer | Risk of burns and heat exposure |

Environmental Resistance | High UV, moisture, and temperature resistance | Limited UV and moisture resistance |

Installation Time | Fast and simple | Takes longer, requires heating tools |

Cost Efficiency | Lower labor costs | Higher material and labor costs |

Long-Term Durability | High, low failure rate | Good, but may develop voids over time |

Initial Cost vs Long-Term Benefits

While cold shrink cable terminations may have a higher initial cost compared to heat shrink alternatives, the savings in labor and reduced downtime make it a cost-effective option for offshore projects in the long run.

Return on Investment

Cold shrink technology offers a higher return on investment due to its faster installation, minimal maintenance requirements, and long-term performance. This makes it a smart choice for offshore projects that require reliable and efficient cable terminations.

Cold shrink cable terminations offer a reliable, efficient, and safe solution for offshore applications. Their tool-free installation, resistance to harsh environments, and long-term durability make them the preferred choice for offshore cable terminations. For offshore projects needing minimal downtime, high safety, and reliable performance, cold shrink technology is the optimal solution. By adopting this technology, companies like Anlian Electric can enhance efficiency and safety in offshore installations, ensuring long-term reliability.

A: Cold shrink cable terminations use pre-expanded elastomeric materials that contract to form a tight seal, providing reliable protection for cables, especially in harsh environments.

A: Cold shrink terminations do not require heat for installation, unlike heat shrink, making them safer and quicker to install, especially in hazardous offshore environments.

A: Cold shrink technology offers excellent resistance to moisture, UV exposure, and temperature extremes, making it perfect for the harsh conditions found in offshore installations.

A: Cold shrink terminations are installed by placing the pre-expanded sleeve over the cable and removing the plastic core, allowing the material to contract and form a secure seal.

A: Yes, cold shrink terminations reduce labor costs due to faster installation times and eliminate the need for specialized tools, offering long-term savings in offshore projects.